facilities.

From our point of view, it is essential to receive feedback from production and commissioning in prototype construction and, if necessary, to be able to carry out preliminary tests. That's why we have a small workshop and various laboratory rooms.

our workshop.

Even if we buy the production of most of the parts externally, it has proven to be very advantageous to have a small workshop available for rework and adjustment work. For this we have a 80m² Workshop with the following equipment:

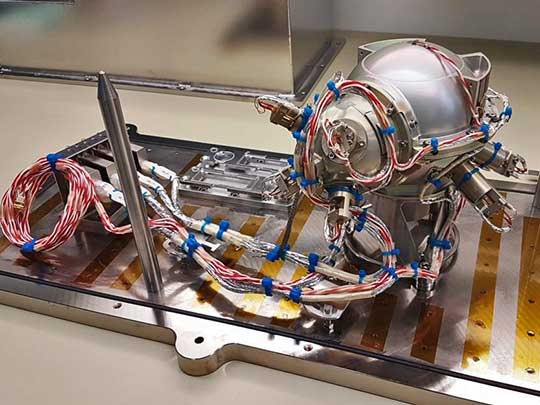

The workshop is also used for pre-assembly and for qualification tests and various measurements. The figure shows the dummy mirror segment of the ESO VLT primary mirror. It is used to measure the forces that occur in the active storage of the mirror shell in operation.

Here, the segment is measured and the center of gravity is determined.

We usually manufacture our test setups ourselves in order to be able to incorporate the gained experience directly. In addition, any necessary adjustments that only become apparent when the tests are carried out can be implemented very quickly.

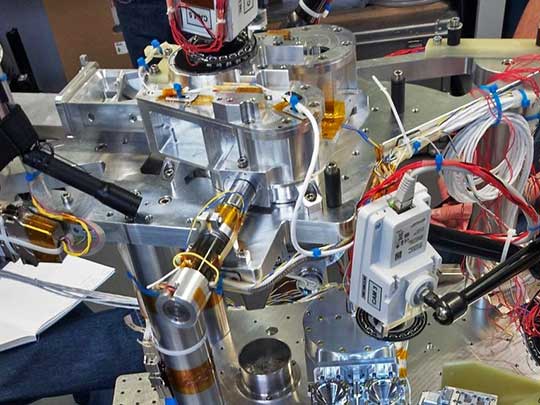

Here, the main vessel flange of a vacuum chamber is manufactured, whereby the plug feedthroughs, cooling lines and the optical ports are manufactured according to experiment requirements.

our labratory.

Equipment:

Clean Bench ISO5 (1x2m), a cleanroom tent was installed in front of the clean bench and a cleanroom air shower with an additional laminar flow module was installed in the entrance to the room. For component cleaning there are several ultrasonic baths, a Miele part washing machine. If necessary, the components can be baked in a thermal vacuum chamber.

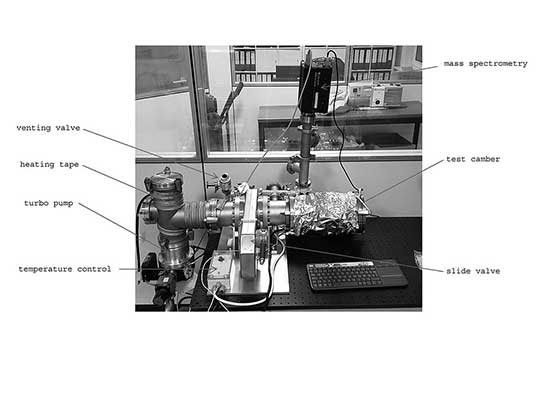

The chambers listed below can be used for baking but also for thermal vacuum tests. A TQCM or a quadrupole mass spectrometer is available for residual gas analysis. If necessary, MOC samples can be installed to the chamber. They will be evaluated at the Frauenhofer Institut IBP. The vacuum chambers themselves, can be tested with a helium leak detector.

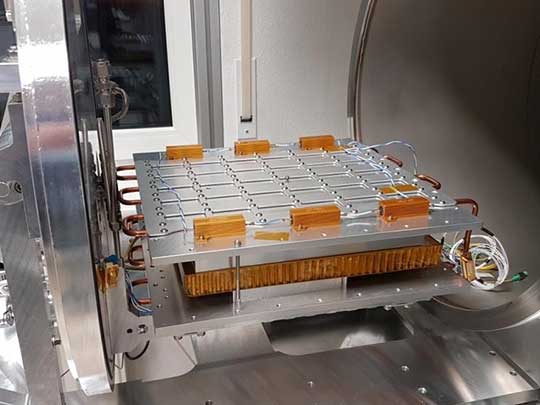

Thermal Vacuum Chamber Di500x480 & opt. bench

The vacuum chamber was designed to carry out measurements on optical systems in vacuum at temperatures between -190 and + 200°C. The fixed boiler flange and the optical bench are mounted vibration-dampened on a common frame, the boiler itself is mounted on rollers.

The vacuum-side optics and the external measuring optics are therefore easily accessible and are not de-adjusted when the chamber is closed. The system is located under a Laminar Flow module.

Thermal Vacuum Test Chamber Di500x480

The vacuum chamber was designed to carry out measurements on mechanical systems in vacuum at temperatures between -190 and + 200°C. It can also be used for baking. The system is located under a Laminar Flow module.

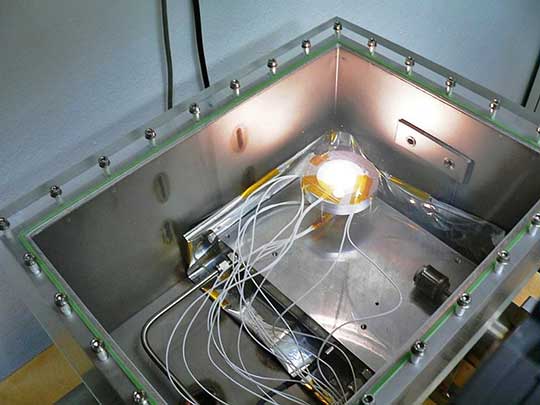

Rectangular chamber (350x250x200mm3)

in which the most diverse tests (thermally cycling of adhesive samples or PCBs, testing of heat transitions on lamps, functional tests on subsystems..), under vacuum (tmin = 5E-6mbar) and at temperatures up to -190°C.

Here, a few other plants are briefly presented.

assembly + testing.

In our premises we have the possibility to assemble and test smaller components. If necessary, smaller breadboards are produced during the design in order to be able to test individual functions in advance.

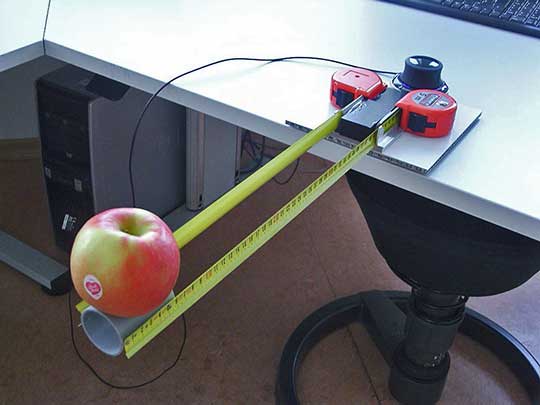

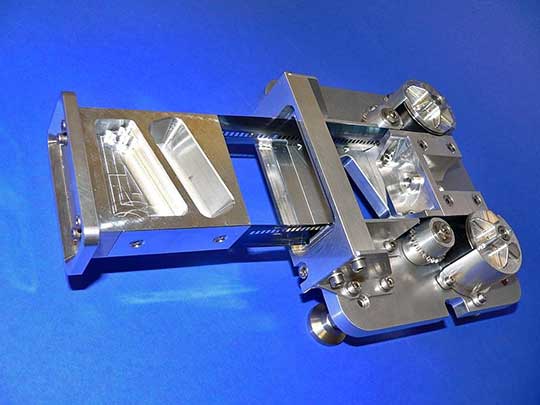

ExoMARS CSTM preliminary development

During the European Mars mission ExoMars, soil samples will be taken and analyzed by a rover. A linear unit was required to transport the drill cores from the drill outside the rover to the rock mill inside. Due to the small space in the rover, conventional linear drives could not be used. This gave rise to the idea of using two sealed tapes.

Using a simple model (2 bands and an apple), the customer could be won over for the idea. Afterwards, a simple model of the mechanics was built and tested. On these foundations, the first real prototype was created.